Our history

1922

Innovation by principle.

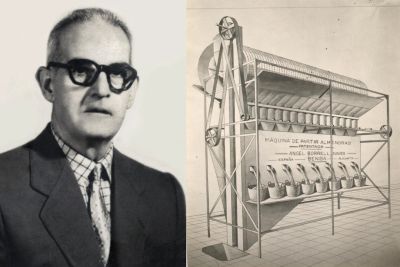

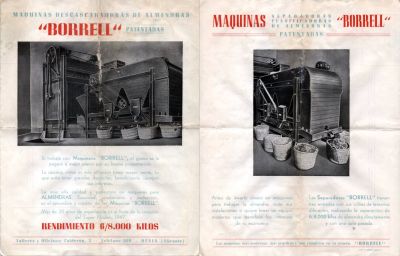

In 1922 Angel Borrell Ivars devised and patented his first almond sheller named "The almond ideal", giving rise to an innovative tradition that continues today.

1925

From the machine to the complete solution.

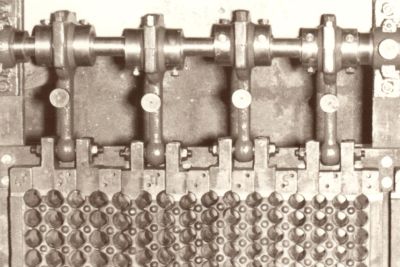

In 1925 the first Borrell separator was patented, laying the foundations for the mechanization of almond processing. Other sorting and sizing machines were soon added to this machine, as well as multiple mechanical improvements.

1935

The improvement of the idea.

In 1932, a new, larger almond craker and sheller was patented. In 1935, a new eccentric shaft system was also patented that eliminated vibrations and significantly improved the performance of the machine.

The success of the mechanical novelties introduced was resounding, which allowed the small workshop still located in Benissa (Alicante, Spain) to dedicate itself almost exclusively to the manufacture of machinery for almonds.

1940

Start over

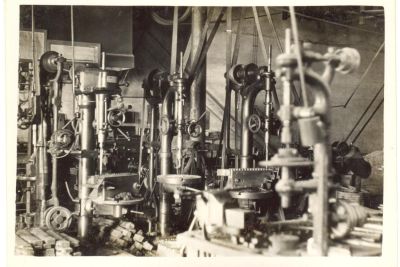

In 1940, once the war in Spain had ended, a new workshop was opened in Dénia (Alicante), where the family had moved at the beginning of the war.

At that time the first employees of the company were hired and the commercial activity was resumed.

1947

New horizons and goals

In 1947 José Borrell Collado assumed the direction of the workshop that his father had founded. At this stage he moved the business to larger premises in Dénia and the first exports of machinery began.

1951

The Borrell® trademark is registered

1960

The beginning of modern manufacturing

1963

New machines for more complete lines

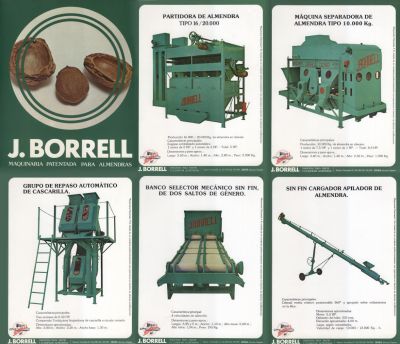

In 1963, the "Model 63" almond shelling line was designed, which made it possible to get greater capacities and performance by optimizing the flow of the product.

The range of available solutions was expanded with new cracking machines for hazelnuts, peach and apricots kernels, pine nuts and other tree nuts.

1968

The evolution of a successful model

In 1968 the "Model 68" complete line type was introduced, further improving quality and performance. In those years the transition to steel manufacturing began, since until then it was only used in mechanical parts.

At the end of the 60s, the collaboration with the company "La Mecánica Jijonenca" began, in order to offer almond blanching equipment and milling machines.

1974

New solutions for new challenges.

The energy and agricultural crises of the 1970s were answered with more efficient, productive and reliable machines together with a new complete processing line named "Model 74"

During this stage, Antonio Roig Álvarez joined the company. His sales management focused on total customer service, which became one of the differentiating features of the company.

1975

A life dedicated to inventing the future

In 1975 Angel Borrell Ivars passed away, leaving behind a life full of epic and transcendental experiences. His restless mind never rested from inventing new machines and mechanisms of all kinds, ideas for which he was awarded with 8 invention patents between 1922 and 1946.

The indelible memory of him means still today an enormous legacy of inspiration and experience.

1976

International expansion and success

At the end of the 70s, the exports of our machines spread throughout Europe, Africa, Asia and America.

Participation in exhibitions and congresses intensifies, since then regularly participating in national and international events.

During this period, the catalog of machines was expanded with new models of elevators, augers, belts, silos, hoppers, blowers and drying equipment.

1984

The dawn of new technologies

During the 80s, the first numerically controlled machine tools (CNC) were incorporated into our manufacturing processes, both for machining and for sheet metal.

Stainless steel manufacturing begins and new welding methods and equipment (MIG/MAG/TIG) are incorporated that will make it possible to design more hygienic machines with higher construction quality.

1987

Ensuring quality and better design.

Investment in new manufacturing technologies (sheet metal punching and cutting lines, profile cutters and CNC bending machines) continued to improve and expand our factory, which allowed us to design increasingly complete machines and lines of higher quality, more reliable and safer.

1989

First complete line for blanching almonds

In 1989, the first almond blanching lines were incorporated into our extensive catalog of solutions.

Since then, this range of machines has not stopped expanding with multiple technological innovations that allow us to offer today unbeatable results in quality, efficiency, production and performance.

1991

Electronics for a new era

In 1991 we integrated electronic sorting machines for the first time in our complete processing lines. Since then we have supplied equipment from different manufacturers, such as ESM®, Satake® and currently the technology provided by Tomra®

1993

Design goes digital

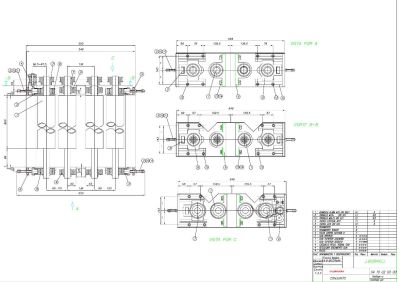

In 1993, the digitization of design and manufacturing began, implementing CAD-CAM systems.

A year earlier, in 1992, the company joined the AIDIMME Technological Institute of Valencia, which stands out for its research and consultancy applied to the metal-mechanic industry.

1995

Exceptional technical service

During the 1990s, the technical customer service was expanded successively and new electrical, electronic and automation departments were created.

Offering the best customer support anywhere and at any time has always been and continues to be our goal.

1998

A factory always at the technological forefront.

In 1998 production was transferred to a new factory located in the Denia Industrial Estate (Alicante).

The new factory was equipped with the most modern and advanced machinery, equipment and facilities, and has not stopped to be renovated and expanded ever since.

2000

Advanced automation for our lines.

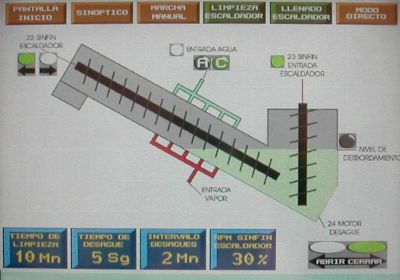

In the year 2000, PLC control and touch screen HMI were introduced in our complete lines, both shelling and blanching.

Since that year, microcontrollers, advanced sensors, control and communication devices have begun to be introduced, which will give rise to a new range in our catalog dedicated to control and automation.

This catalog today includes Borrell Automation® proprietary devices and Borrell PlantManager® computer process control software.

2001

Jośe Borrell awarded with the "INC Golden Tree Nut"

Jośe Borrell receives the "Golden Tree Nut" award The company José Borrell S.A. was awarded the "Golden Tree Nut" prize at the INC (International Nut Council) Congress that was held in Barcelona in 2001 and commemorated its 30th edition.

The same year, the company became associated with the AINIA Technological Institute of Valencia, specialized in research and food technology, with which multiple projects were developed in subsequent years.

2002

Advanced engineering and design.

In 2002, the implementation of new three-dimensional parametric design (3D CAD) tools began together with solutions for mechanical, load and fluid simulation.

Added to these improvements were new CAD/CAM programming and simulation systems for laser cutting, punching and machining machines that were added or renovated in our factory.

2005

R + D + I Generalitat Valenciana Award granted by AEFA

2007

More state-of-the-art design and manufacturing technology

2008

More productive machines and complete lines

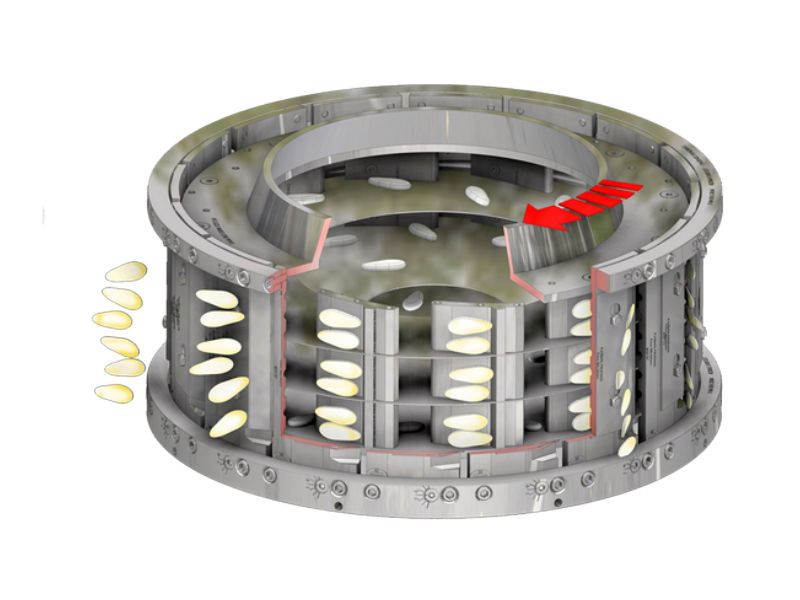

Between 2006 and 2008, new complete and automated almond processing lines were launched, both for pre-cleaning, shelling, blanching, slicing, drying, cooling, sizing, pasteurization, industrial control, weighing and packaging.

2009

Borrell USA Corp, new headquarters in the United States.

Borrell USA Corp was created in 2009 to allow us to offer better service and attention to our customers in the main almond producing area in the world.

The company, located in Merced, California, has spacious offices, spare parts warehouses, an exhibition area, a mechanical workshop, and space for future manufacturing and assembly operations.

2011

A new generation of unbeatable machines

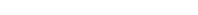

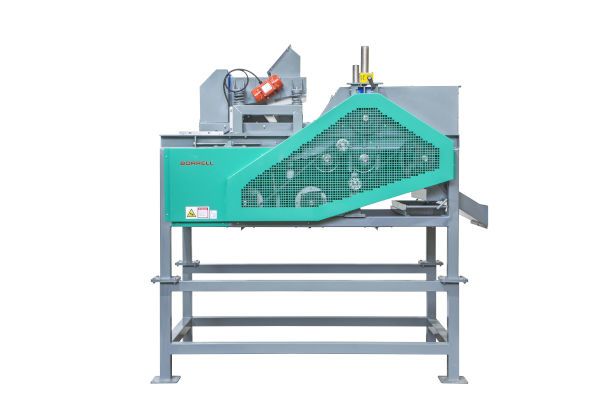

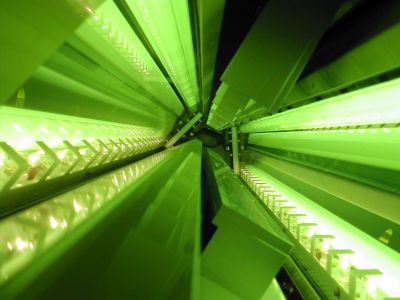

Between 2010 and 2012, a new milestone was reached with the launch of the Borrell Smart Sorter® range and the new patents for heat treatment, pasteurization, and almond blanching equipment, among others.

The solutions catalog was completed with our new Taming Sun® kilns, dryers and coolers, new shellers and FAM® Centris® slicers.

2013

An example of success and entrepreneurial vision.

In 2013, José Borrell Collado passed away at the age of 91. His tireless dedication and creative talent earned him 16 invention patents during a career full of technological and business successes.

2018

We achieve +60 own patents

We obtained new patents for Borrell Huller Combo® shelling machines, HyperQuadro® shelling systems, Borrell Smart Shelling System® advanced control systems, Borrell Smart Elevator® elevators, among others.

The company has accumulated more than 60 patents of its own, with 35 of them obtained in the last 10 years.

2019

Growing up together

In 2019 José Borrell S.A. becomes the reference industrial shareholder of Mecánica Jijoinenca S.A. (Mejisa), reinforcing the links and technological collaboration between both companies.

We started new R+D projects, among which the collaboration with the University of Alicante, the Polytechnic University of Valencia stand out.

2021

True breaktrough technology

In 2021, a new investment cycle in machine tools and state-of-the-art equipment is completed, with new multi-axis machining centers, CNC lathes, sheet metal cutting lines, a new robotic welding cell, among other improvements.

The constant investment in R&D continues to produce new designs, new patents and new opportunities to continue offering our customers the most advanced and productive machinery.

2022

We celebrate 100 years leading innovation in machinery and technology for tree nuts.

At Borrell we continue to work inspired by the accumulated experience and maintaining our fidelity with constant innovation, quality manufacturing and total customer service.

We continue to grow and provide new technological solutions to overcome the most demanding challenges and achieve an increasingly adequate and efficient processing of almonds and other nuts.

2024

A New Chapter in California - Starting Manufacturing Operations and Expanding Our Technical Team in the USA

A significant milestone for BORRELL® USA, 2024 marks the initiation of our local manufacturing operations in Merced, California, and the expansion of our technical team across the United States.

This year signifies not just the establishment of our state-of-the-art manufacturing facility but also a strengthening of our commitment to innovation, quality, and customer service in the North American market. With these developments, BORRELL® USA is poised to reach new heights in the nut and almond processing industry, offering cutting-edge solutions and unparalleled technical support.