Borrell xPLC PlantManager®

Streamlining industrial process control for a smarter, more efficient future.

Our software suite facilitates seamless interaction between machinery on the industrial line and the company network. It enables real-time monitoring, control, and data acquisition, making it an indispensable tool for modern industrial environments.

Borrell xPLC PlantManager®

Key Features

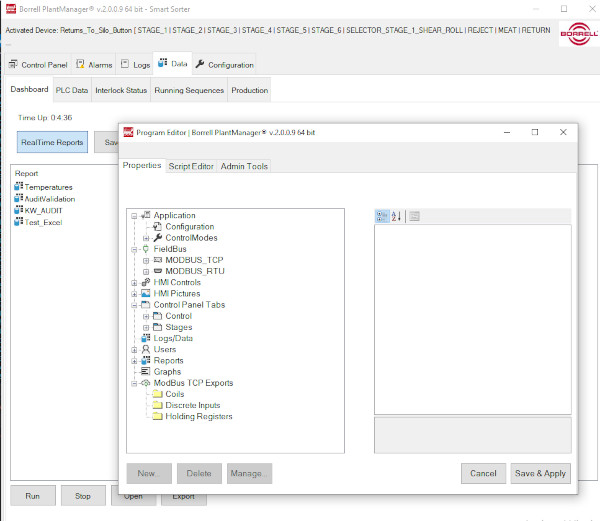

Our software integrates PLC, HMI, IDE, and SCADA functionalities, delivering unparalleled efficiency and flexibility for your industrial operations.

Programmable Logic Controller (PLC):

Executes logical instructions and manages machine operations.

Allows for the quick programming and control of logic and sequences within the industrial line.

Human-Machine Interface (HMI):

Provides a visual and intuitive platform for operators and supervisors.

Real-time data visualization, alarms, and machine statuses for efficient oversight.

Integrated Development Environment (IDE):

Streamlines the creation and modification of PLC logic and HMI elements.

Facilitates the development of customized programs tailored to specific industrial needs.

Supervisory Control and Data Acquisition (SCADA):

Collects, processes, and presents real-time data from machinery and sensors.

Offers graphical representation, reporting, and alarm capabilities.

Versatile Communication Protocols

The Borrell xPLC PlantManager® platform supports a variety of communication protocols to ensure seamless data exchange across your industrial systems:

Modbus®TCP and Modbus®RTU

Efficient data read and write operations with Modbus-compatible devices.

HTTP/REST & Database

Secure data transfer through HTTP/REST JSON requests, supporting integration with databases, SQL queries and external applications.

MQTT

Optional modules for efficient communication in IoT contexts, supporting remote monitoring.

OPC-UA®

Optional gateway to the standardized and secure communication framework for interoperability across different devices and platforms.

Integration with Borrell® machinery

Support for all proprietary and third-party protocols (RS485/232/422 & TCP/UDP) used in Borrell® industrial lines.

Customization and Expansion

Possibility of customizations and development of functionalities and code on demand.

Get to know our application platform

Borrell xPLC PlantManager® offers a variety of versions tailored to the specific needs of each automation project, with different implementations, platforms, and optional modules.

Borrell xPLC Plant Manager® LT

Compact version with basic features and quick deployment, optimized for the control of Borrell® machines and processing lines.

-

Platform:

MS Windows® 8 x86/x64

MS Windows® 10 x64

MS Windows® 11 x64

-

License:

-

Current Version:

2.0.10 (Release)

-

Included modules:

- HMI

- SPLC

- IDE

- Logs

- Reports

- Recipes/Profiles

- User Levels

- Scripting

- Modbus®(RTU/TCP)

- RS485/RS232

- JSON Data Source

- WebView

- CSV/XLS Export

- SCADA Lite

-

Optional modules:

- Database Reports

- OPC-UA Gateway

- EtherIP Protocol

- OBDC

- REST API

- InfluxDB/Grafana Sync

- Web Interface

- SCADA Extended

- Advanced Permissions

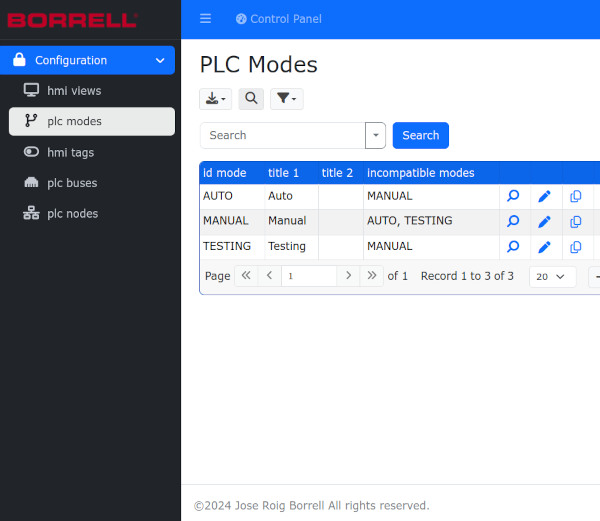

Borrell xPLC Plant Manager® NG

Multiplatform network server version with integrated database and various alternative web and desktop interfaces.

-

Platform:

GNU/Linux®

MS Windows®

Apple IOs®

-

License:

-

Current Version:

0.9.0 (Beta)

-

Included modules:

- Real Time Database

- Web HMI

- Web IDE

- SPLC

- Modbus® TCP/RTU

- RS485/RS232

- JSON Data Source

- SQL Data source

- OPC-UA Server/Client

- NodeRED Connector

- REST API

- Security & Audit

- Advanced Scripting

- SCADA Tools

-

Optional modules:

- EtherIP Protocol

- CAN Bus

- MQTT

- Z-Wave

- ZigBee

- SDK

- InfluxDB/Grafana Sync

- SCADA Extended

- Production Control Extended

- Production Planner

- Traceability Module

- Access Control - CCTV

- Server Admin Tools

Borrell xPLC Plant Manager® OS

Coming soon! NG version distributed as core Operating System of Borrell Automation® PLCs (ARM64/x86/x64)

-

Platform:

GNU Linux® x86/x64/ARM

-

License:

-

Current Version:

0.2.1 (Aplha)

Why Choose Borrell xPLC PlantManager®?

Choose Borrell xPLC PlantManager® for its seamless integration of PLC, HMI, IDE, and SCADA functionalities, robust data exchange, and flexible customization options. It reduces obsolescence, lowers maintenance costs, and leverages modern computational power, making it an efficient and cost-effective solution for industrial automation.

Reduced Obsolescence:

Easily updatable software extends system lifespan and reduces long-term costs.

Hardware Flexibility:

Adaptable to various hardware components from different manufacturers.

User-Friendly Interface:

Graphical interface designer for intuitive process visualization.

Short Implementation Time:

Dialog-based configuration and programming, with support for editing and running scripts in JavaScript (V8) and VBScript.

FAQ

Currently, the applications of the Borrell xPLC PlantManager® platform are exclusively available to clients who engage in automation projects with Borrell Machinery® and Borrell Automation® electronic devices.

In addition to the modules included in the standard version, there is the option to integrate additional modules, which may have varying requirements, licenses, or costs. For more information on how to obtain Borrell xPLC PlantManager® and customize it to your specific needs, please contact our sales team or visit our support page.

We are planning to expand the distribution of future versions of the software to the general public. Announcements will be made on this website.

In addition, the open-source code, whether our own or third-party, used in some versions of our software will be available on our GitHub repository.

The Borrell xPLC PlantManager® LT software is distributed under the Borrell Software License, described here. Other versions or applications may be distributed under different combinations of licenses, including open-source licenses, in which case the source code is distributed along with the software. Optional modules come with various pricing and licensing options, including third-party licenses. Please refer to each module's specifications for more information.

Yes, we offer maintenance and support services. We perform installations and configurations at the client's premises and provide remote support, tele-maintenance, and remote connection services upon request. There are various types of support programs and maintenance contracts available. Please contact our sales team for more information.